-

Preforms Assembling

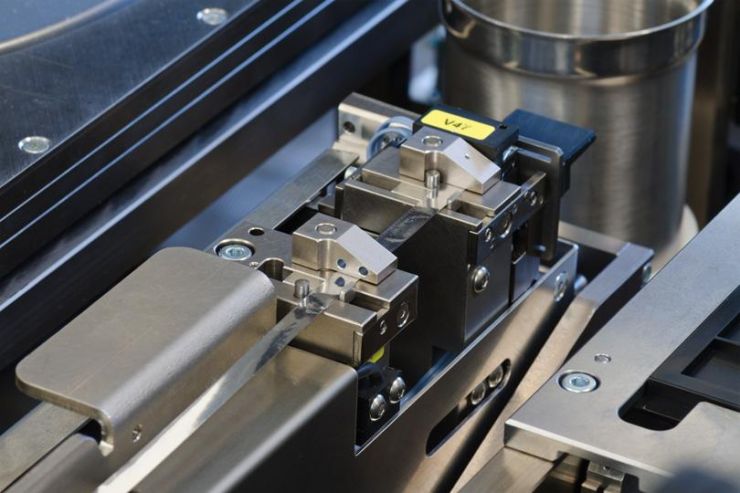

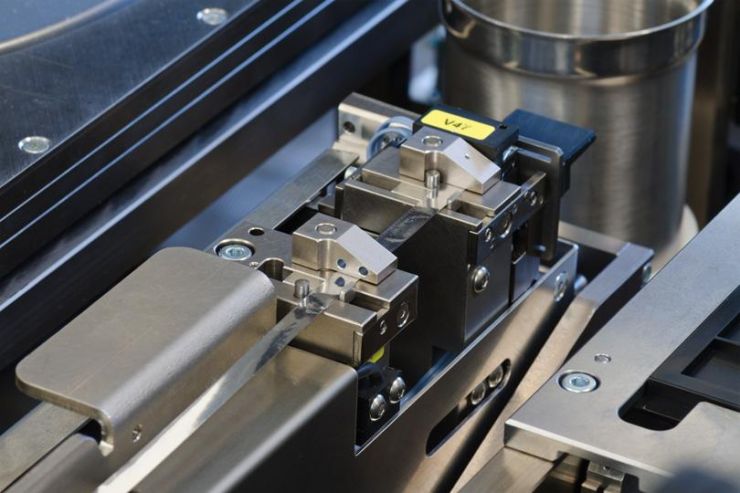

Flux-free solder connections are essential in power module production. Therefore, instead of solder paste, so-called solder preforms are used. The preforms are fed to the assembler on reels and cut to the required length directly on the machine.The assembly head picks them from the feeder with special nozzles, guaranteeing an absolute evenness of the preform, and then places them correctly and precisely onto the substrate.

Depending on the cycle time requirements, the assembling of the preforms and the power semiconductor, as well as the dispensing of a bonding agent can be conducted on the same machine.

The preform feeder can easily be changed without opening the machine door. On an external setup station, new solder tapes can be equipped and prepared for their next use.

-

Die Bonding

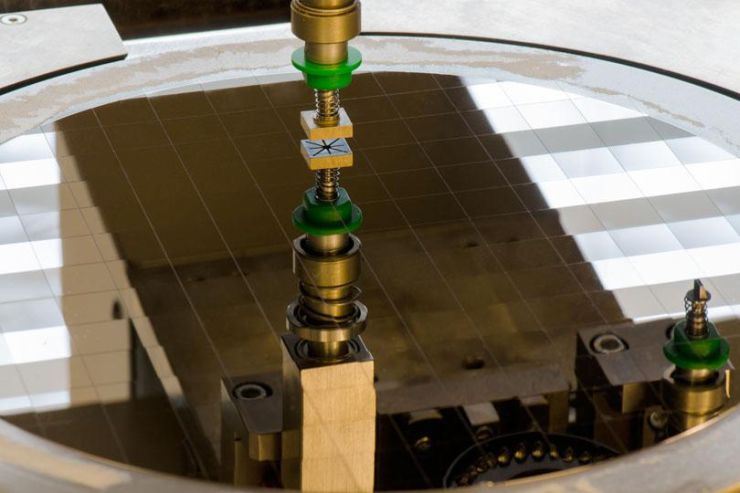

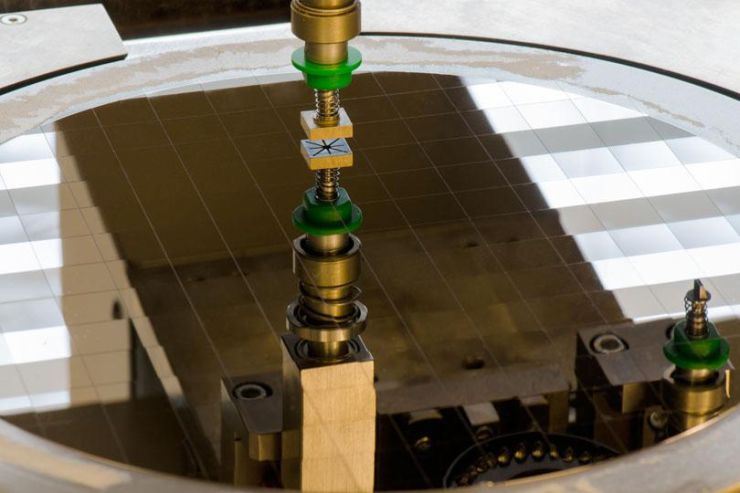

The assembly of power semiconductors (IGBT, diodes) on the substrates is a relatively standard process. Our solution offers the advantage that the power semiconductor can be directly assembled from the wafer onto the substrates in a large-scale oven carrier. Thus, the repositioning of the substrates from a small workpiece carrier into the oven carrier can be omitted.

Moreover, the power semiconductors have a large edge length and are quite thin requiring an ejection from wafer with a needle bed. Thereby ensuring that no cracks in the chip occur. Even inaccurately mounted wafers can be automatically oriented in their rotational position and correctly aligned to the portal, so that the multiple needles are able to meet the chip.

If required, the assembling of the preforms and the power semiconductor as well as the dispensing of a bonding agent, can be conducted on the same machine, depending on the cycle time requirements.

-

Gel Dispensing

Flyer - Power Module

The assembled and wired power modules must be covered by a polyimide insulation layer. Thereby, the surfaces of the power semiconductor as well as the bond wires or specific boundary areas must be covered very accurately. The fully integrated vision system uses the specific structures on the substrates to align the dispensing system exactly to the target position.Normally, jetting is used as a common dispensing technique. The Infotech Component Matrix offers a multitude of modules for purging, cleaning and recalibrating dispense systems as well as for process and quality monitoring.

-

Press-in

Flyer - Power Module

The assembled and soldered power electronics module must be able to connect to the outside, i.e. to the package and its housings. Various processes exist to assist in these circumstances. One of such processes consists of picking up the contact pins provided as bulk goods, turning them in an upright position and pressing them into the pin housings pre-assembled on the module. The force-displacement diagram is then recorded during the process and forwarded to the appropriate server in a suitable form for traceability purposes.

-

Preforms Assembling

Flux-free solder connections are essential in power module production. Therefore, instead of solder paste, so-called solder preforms are used. The preforms are fed to the assembler on reels and cut to the required length directly on the machine.The assembly head picks them from the feeder with special nozzles, guaranteeing an absolute evenness of the preform, and then places them correctly and precisely onto the substrate.

Depending on the cycle time requirements, the assembling of the preforms and the power semiconductor, as well as the dispensing of a bonding agent can be conducted on the same machine.

The preform feeder can easily be changed without opening the machine door. On an external setup station, new solder tapes can be equipped and prepared for their next use.

-

Die Bonding

The assembly of power semiconductors (IGBT, diodes) on the substrates is a relatively standard process. Our solution offers the advantage that the power semiconductor can be directly assembled from the wafer onto the substrates in a large-scale oven carrier. Thus, the repositioning of the substrates from a small workpiece carrier into the oven carrier can be omitted.

Moreover, the power semiconductors have a large edge length and are quite thin requiring an ejection from wafer with a needle bed. Thereby ensuring that no cracks in the chip occur. Even inaccurately mounted wafers can be automatically oriented in their rotational position and correctly aligned to the portal, so that the multiple needles are able to meet the chip.

If required, the assembling of the preforms and the power semiconductor as well as the dispensing of a bonding agent, can be conducted on the same machine, depending on the cycle time requirements.

-

Gel Dispensing

The assembled and wired power modules must be covered by a polyimide insulation layer. Thereby, the surfaces of the power semiconductor as well as the bond wires or specific boundary areas must be covered very accurately. The fully integrated vision system uses the specific structures on the substrates to align the dispensing system exactly to the target position.

Normally, jetting is used as a common dispensing technique. The Infotech Component Matrix offers a multitude of modules for purging, cleaning and recalibrating dispense systems as well as for process and quality monitoring.

-

Press-in

Flyer - Power Module

The assembled and soldered power electronics module must be able to connect to the outside, i.e. to the package and its housings. Various processes exist to assist in these circumstances. One of such processes consists of picking up the contact pins provided as bulk goods, turning them in an upright position and pressing them into the pin housings pre-assembled on the module. The force-displacement diagram is then recorded during the process and forwarded to the appropriate server in a suitable form for traceability purposes.