-

Chip Testing

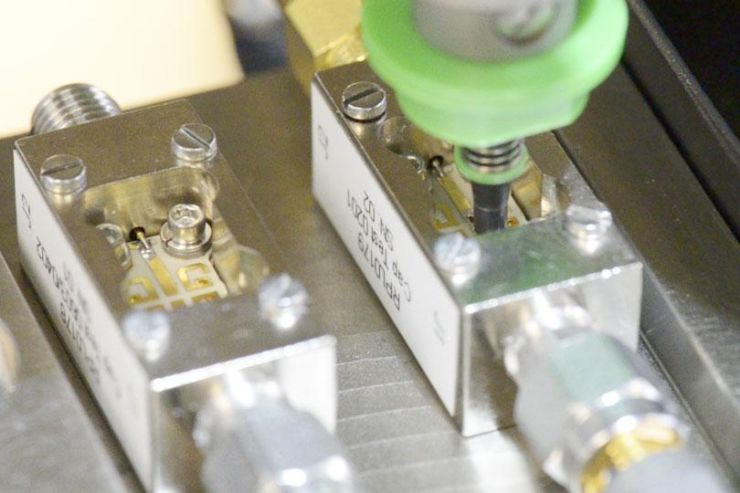

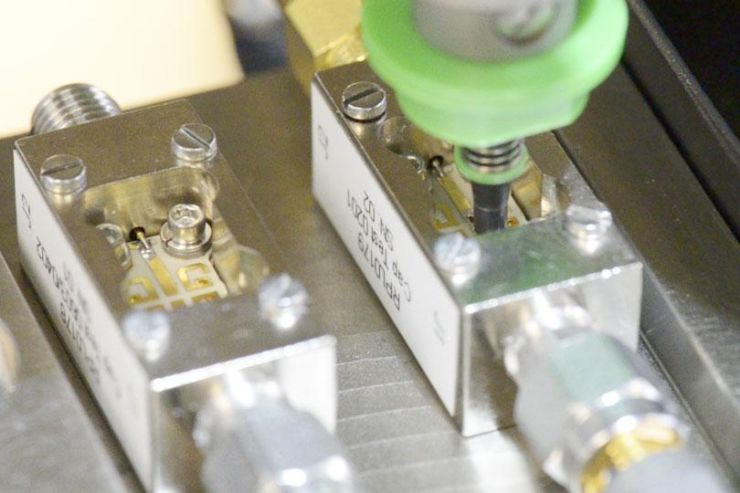

After manufacturing, electronic components are checked to uphold the demanded criteria and then sorted out. Special test systems, which are built especially for this purpose, are often used. However, sometimes there are special test cases, for which a flexible solution is required. The Infotech Component Matrix contains all modules necessary for the completition of such testing tasks. Normally, the actual test unit or test chamber is provided by specialized companies or by the customer. Infotech manages the reliable handling from the feeding of the untested parts to the test chamber and the sorting in the demanded output format. The integrated vision unit supports the localization and position detection of the parts. However, it can also assume responsibility for the visual part inspection.

-

Inspection

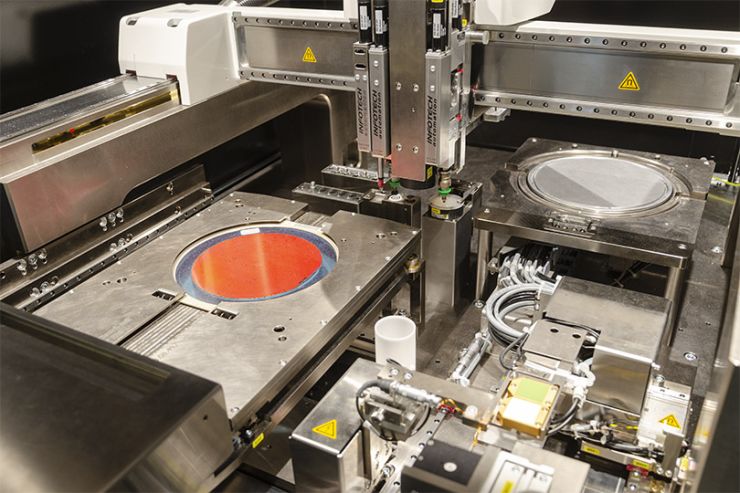

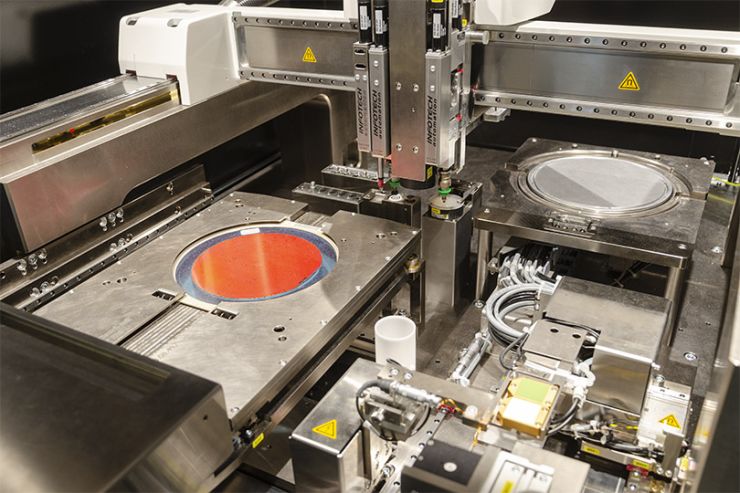

Sorting is often accompanied by inspection and testing tasks. This includes the classic die sorting, where the chips are sorted into different output formats according to so-called bin classes based on a wafer map file or other characteristics.

Optical and electrical inspection and sorting tasks are also frequently used to increase the quality in a production line. Especially in the production of power modules, partial discharge tests or known good device tests are indispensable in meeting high quality requirements.

The test unit is usually provided by third party suppliers and integrated into a compact sorting system by Infotech. Our strength: the flexible handling of the DUTs from feeding to testing and sorting into different output formats.

-

Chip Testing

After manufacturing, electronic components are checked to uphold the demanded criteria and then sorted out. Special test systems, which are built especially for this purpose, are often used. However, sometimes there are special test cases, for which a flexible solution is required. The Infotech Component Matrix contains all modules necessary for the completition of such testing tasks. Normally, the actual test unit or test chamber is provided by specialized companies or by the customer. Infotech manages the reliable handling from the feeding of the untested parts to the test chamber and the sorting in the demanded output format. The integrated vision unit supports the localization and position detection of the parts. However, it can also assume responsibility for the visual part inspection.

-

Inspection

Sorting is often accompanied by inspection and testing tasks. This includes the classic die sorting, where the chips are sorted into different output formats according to so-called bin classes based on a wafer map file or other characteristics.

Optical and electrical inspection and sorting tasks are also frequently used to increase the quality in a production line. Especially in the production of power modules, partial discharge tests or known good device tests are indispensable in meeting high quality requirements.

The test unit is usually provided by third party suppliers and integrated into a compact sorting system by Infotech. Our strength: the flexible handling of the DUTs from feeding to testing and sorting into different output formats.