-

Ultrasonic Welder

Ultrasonic Welder -

Sinter Bonder

Sinter Bonder -

Power Module Die Bonder

Power Module Die Bonder -

Desktop Sinter Bonder

Desktop Sinter Bonder -

Preforms Assembler

Preforms Assembler -

Pin Attacher

Pin Attacher -

Production Lines

Production Lines

-

Ultrasonic Welder

Schunk Sonosystems and Infotech

Thanks to intensive fundamental research and a host of innovations, Schunk Sonosystems has achieved a major technological lead in ultrasonic metal welding and Infotech in fully automated power module production lines.

The Schunk Sonosystems 35kHz ultrasonic welding head with the flexural Sonotrode type performing within the Infotech proven automation platform, supported with peripherals from the Infotech component matrix, allows fully automated ultrasonic welding processes of pin housings or any leads e.g. from lead frames anywhere in the assembly line where it is needed. -

Sinter Bonder

Flyer - Sinter Bonder

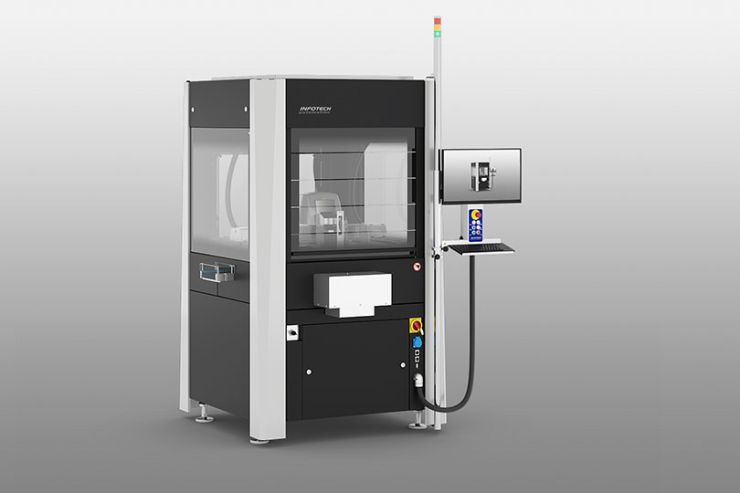

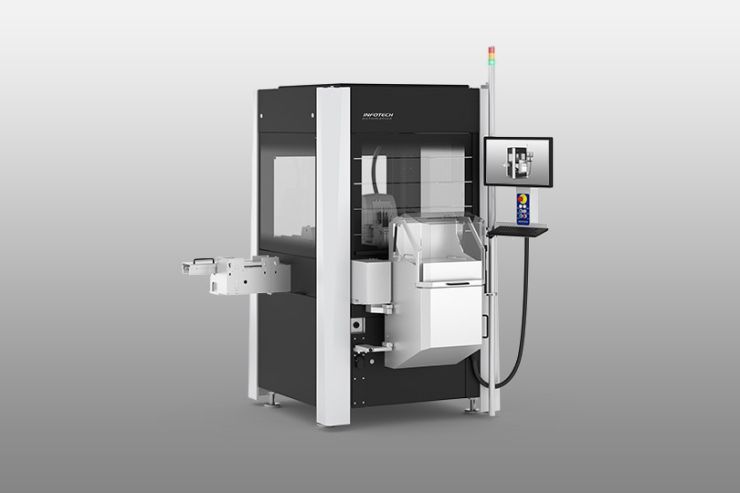

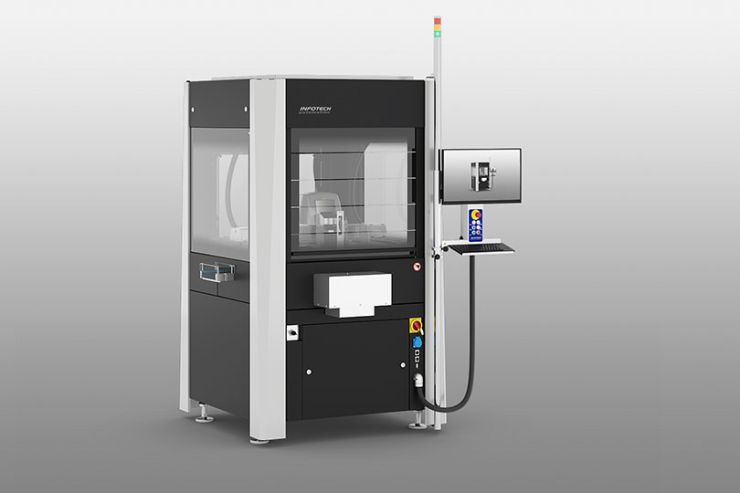

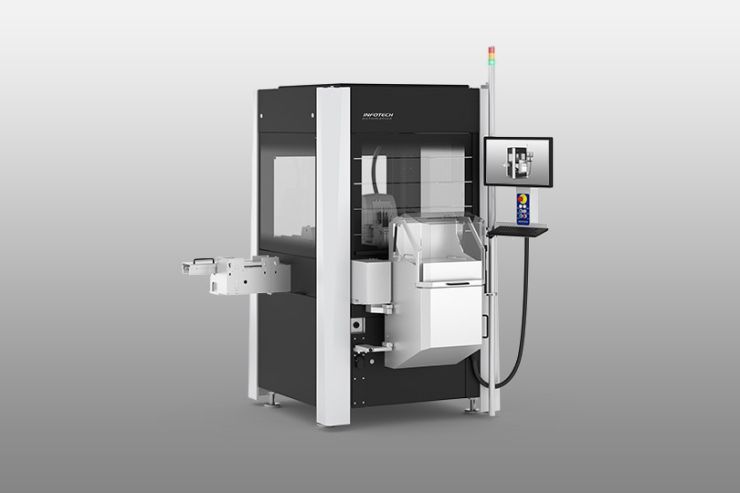

Applications - Power Module ProductionThe sinter bonder fulfills die attach requirements for power electronics exceeding standard die bonder capabilities from laboratory (batch processing) up to series production as fully automated inline system.

The highly flexible die bonder is equipped with sintering process specific components out of Infotech`s component matrix. Heated bond head with high force capabilities, substrate pre-heater and heater station with integrated force measurement, DTF feeder and more are part of the Infotech sinter bonder.

For larger die sizes, the sinter bonder pre-sinters tacks the die onto the DBC substrate where a sinter press performs the final sinter process. For smaller dies, e.g. LEDs, the sinter bonder can completely sinter the LED onto the substrate.

-

Power Module Die Bonder

Flyer - Power Module

Applications - Power Module ProductionIn contrast to classical die bonding, power module manufacturing has special requirements. In general, power MOSFET's, IGBT's and diodes are ejected from the wafer and placed on a DBC substrate supplied in large workpiece carriers. The Infotech Power Module Die Bonder has the advantage of a big work area, which allows placing the products directly onto the workpiece carrier of the vacuum oven, without reloading the substrates.

Moreover, solder preforms can be fed into the machine directly from reel and then cut and placed.In order to attach the power semiconductor, either a bonding agent can be dispensed or a graphite jig or other weights can be automatically put on top of the assembly.

-

Desktop Sinter Bonder

Flyer - Sinter Bonder

Applications - Power Module Production

The desktop sinter bonder dedicated for presinter- and sinter applications with wide open application range for manual, semi automated or fully automated operations.The Lab solution to develop pre-sinter processes with production equivalent process peripherals – for initial series production where the process parameters can be merged into the final production line solution.

Out of Infotech’s component matrix, the system is equipped with sintering process specific components, i.e. heated bond head with high force capabilities, heated substrate holder plate with manual tilt adjustment and integrated force sensing table, two heated bond heads and more.

-

Preforms Assembler

Applications - Power Module Production

Solder preforms are often used in power semiconductor modules or in sensor manufacturing to avoid the application of flux.

Infotech offers the capability of feeding and processing of solder preforms from a reel instead of precut preforms in waffle trays. The standard Preforms Assembler can be equipped with up to four feeders, which are able to cut directly on the machine different widths of preforms at the required size. These preforms can afterwards be precisely picked and placed with up to four assembly heads. With the vision system, each step of the process can be monitored and controlled.

The feeders are able to be exchanged while the assembler is in operation. On an external setup station, they are prepared for the next use. -

Pin Attacher

Flyer - Pin Attacher

Applications - Power Module ProductionThe Pin Attacher fulfills the pin insert requirements for power electronic modules on DBC- and on module-level. Different type of pins are supported, all of which can be fed into a loose form. The pins are flipped into the corrected vertical direction and inserted into the pin housing using force control processes. The force profile is logged per pin and can be available as part of the traceability data. Up to six heads are working simultaneously.

-

Production Lines

Flyer - Power Module

Applications - Power Module Production

In the field of Power Module Production Infotech offers solutions for separate processes, complete production cells or entire production lines. Variable transport systems enable the processing of customer specific work piece carrier with a width up to 330 mm and are therefore compatible with oversized vacuum soldering systems. The work piece carrier can be returned within the production line and circulate autonomously through the process steps “assembling”, “soldering” and “unloading”.

-

Ultrasonic Welder

Schunk Sonosystems and Infotech

Thanks to intensive fundamental research and a host of innovations, Schunk Sonosystems has achieved a major technological lead in ultrasonic metal welding and Infotech in fully automated power module production lines.

The Schunk Sonosystems 35kHz ultrasonic welding head with the flexural Sonotrode type performing within the Infotech proven automation platform, supported with peripherals from the Infotech component matrix, allows fully automated ultrasonic welding processes of pin housings or any leads e.g. from lead frames anywhere in the assembly line where it is needed. -

Sinter Bonder

Flyer - Sinter Bonder

Applications - Power Module ProductionThe sinter bonder fulfills die attach requirements for power electronics exceeding standard die bonder capabilities from laboratory (batch processing) up to series production as fully automated inline system.

The highly flexible die bonder is equipped with sintering process specific components out of Infotech`s component matrix. Heated bond head with high force capabilities, substrate pre-heater and heater station with integrated force measurement, DTF feeder and more are part of the Infotech sinter bonder.

For larger die sizes, the sinter bonder pre-sinters tacks the die onto the DBC substrate where a sinter press performs the final sinter process. For smaller dies, e.g. LEDs, the sinter bonder can completely sinter the LED onto the substrate.

-

Power Module Die Bonder

Flyer - Power Module

Applications - Power Module ProductionIn contrast to classical die bonding, power module manufacturing has special requirements. In general, power MOSFET's, IGBT's and diodes are ejected from the wafer and placed on a DBC substrate supplied in large workpiece carriers. The Infotech Power Module Die Bonder has the advantage of a big work area, which allows placing the products directly onto the workpiece carrier of the vacuum oven, without reloading the substrates.

Moreover, solder preforms can be fed into the machine directly from reel and then cut and placed.In order to attach the power semiconductor, either a bonding agent can be dispensed or a graphite jig or other weights can be automatically put on top of the assembly.

-

Desktop Sinter Bonder

Flyer - Sinter Bonder

Applications - Power Module Production

The desktop sinter bonder dedicated for presinter- and sinter applications with wide open application range for manual, semi automated or fully automated operations.The Lab solution to develop pre-sinter processes with production equivalent process peripherals – for initial series production where the process parameters can be merged into the final production line solution.

Out of Infotech’s component matrix, the system is equipped with sintering process specific components, i.e. heated bond head with high force capabilities, heated substrate holder plate with manual tilt adjustment and integrated force sensing table, two heated bond heads and more.

-

Preforms Assembler

Applications - Power Module Production

Solder preforms are often used in power semiconductor modules or in sensor manufacturing to avoid the application of flux.

Infotech offers the capability of feeding and processing of solder preforms from a reel instead of precut preforms in waffle trays. The standard Preforms Assembler can be equipped with up to four feeders, which are able to cut directly on the machine different widths of preforms at the required size. These preforms can afterwards be precisely picked and placed with up to four assembly heads. With the vision system, each step of the process can be monitored and controlled.

The feeders are able to be exchanged while the assembler is in operation. On an external setup station, they are prepared for the next use. -

Pin Attacher

Flyer - Pin Attacher

Applications - Power Module ProductionThe Pin Attacher fulfills the pin insert requirements for power electronic modules on DBC- and on module-level. Different type of pins are supported, all of which can be fed into a loose form. The pins are flipped into the corrected vertical direction and inserted into the pin housing using force control processes. The force profile is logged per pin and can be available as part of the traceability data. Up to six heads are working simultaneously.

-

Production Lines

Flyer - Power Module

Applications - Power Module Production

In the field of Power Module Production Infotech offers solutions for separate processes, complete production cells or entire production lines. Variable transport systems enable the processing of customer specific work piece carrier with a width up to 330 mm and are therefore compatible with oversized vacuum soldering systems. The work piece carrier can be returned within the production line and circulate autonomously through the process steps “assembling”, “soldering” and “unloading”.